Prototypes creation uses a big range of technologies. However, despite the big differences that we can identify, we can group and classify them in two big categories: additive production and subtractive production.

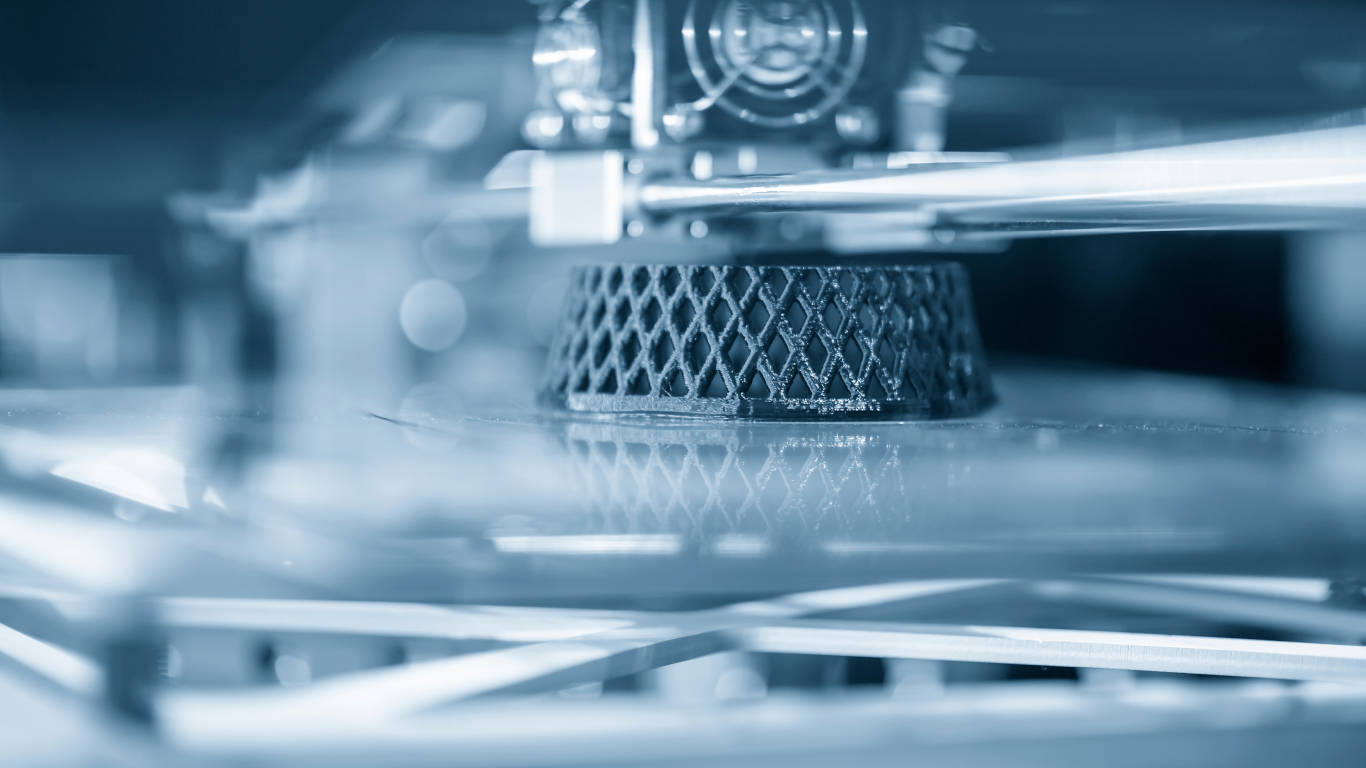

These two methods are diametrically opposed: additive manufacturing builds the products adding material, meaning that the prototype is created layer upon layer. Subtractive manufacturing, instead, uses a starting block from which excessive material is removed to shape the required geometry.

Starting from the two different methodologies presented, we can select the best alternative for the client, since both have advantages and disadvantages. There is no perfect solution. That is why relying on experts to get proper advice is fundamental to meet the requests and be efficient.

Additive manufacturing advantages are the following:

- Rapid delivery times;

- The possibility of building complex shapes (such as details with undercuts);

- The creation of different variants of the same item in a single working section, without designing and realizing dedicated equipment.

Subtractive manufacturing advantages are the following:

- Working on a whole solid piece, problems related to the material porosity (that comes from layers) are eliminated;

- Particulars in every single rigid material can be realised;

- The final product has no roughness and there is no need to use after-processing finishing.

- In the case of big volumes, subtractive technique is cheaper.

The two techniques, despite differences, can be combined to compensate for advantages and disadvantages. Partec offers both the alternatives, so that every single request can be met professionally. Our advice focuses on solving problems related to timing, amount required, use, geometry.

Since 199, PARTEC is the perfect partner for those companies that want to shape their ideas into winning projects.

Contact us to discover more about what we can offer to you.