Partec Srl

Via Costa Erta, 21

24020 – Parre (BG)

P.iva 02657020166

Tel: +39 035-705800

Fax: +39 035-705820

Email: info@partec.it

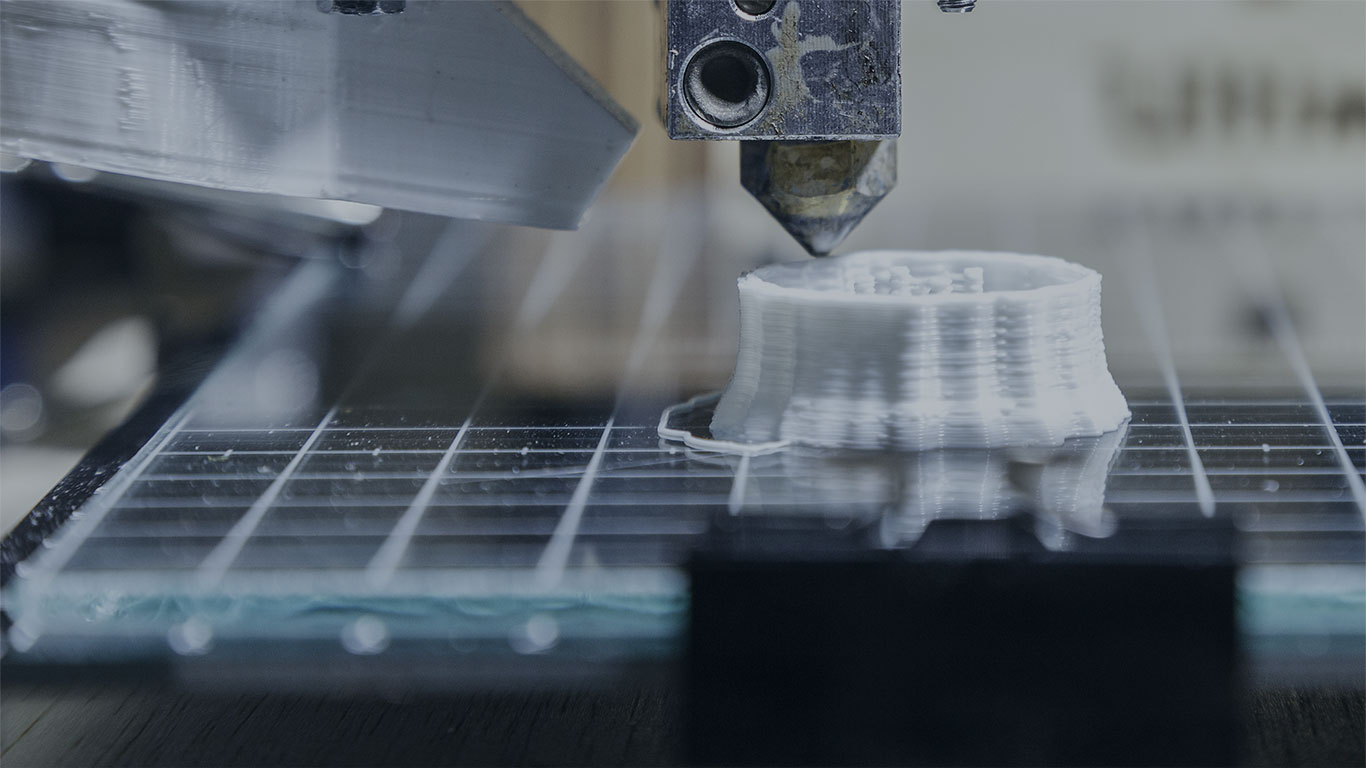

The FDM (Fused Deposition Modeling) process is an additive technology that allows you to make parts in thermoplastic polymers, through a process of deposition of the molten material. The FDM permits the realization of prototypes with valuable functional characteristics thanks to the great quality of the materials that can be used and their individual properties. Partec, with the help of its machinery, manufactures robust prototypes in different materials: ABS, PC, ULTEM and several others. Each one of these materials typify the uses of the model created: if we consider, for example, the purpose at high temperatures for a FDM prototype, ULTEM is the best material to choose.

|

A benefit of this technology is the possibility of creating prototypes, also parts with medium or large dimensions, with the excellent combination between the mechanical properties of the part and the timing of the production of the pieces.

The FDM employes performing materials also used in various industrial sectors (food, aerospace, medical, etc.).

Following the surfaces of the 3D model, the machine defines a tool path and the 3D printer extrudes a filament of melted thermoplastic material from a nozzle and deposits it in layers in order to build the part from the bottom upwards. This operation makes even very complex parts, for the presence of undercuts for example, easy to produce.