Rapid prototyping technologies allow the realization of model with aesthetic characteristics and performance levels, which are comparable to the ones of the final product. For instance, Fused Deposition Modeling (FDM) uses the same thermoplastics required in different industrial sectors: food, medical, automotive and aerospace.

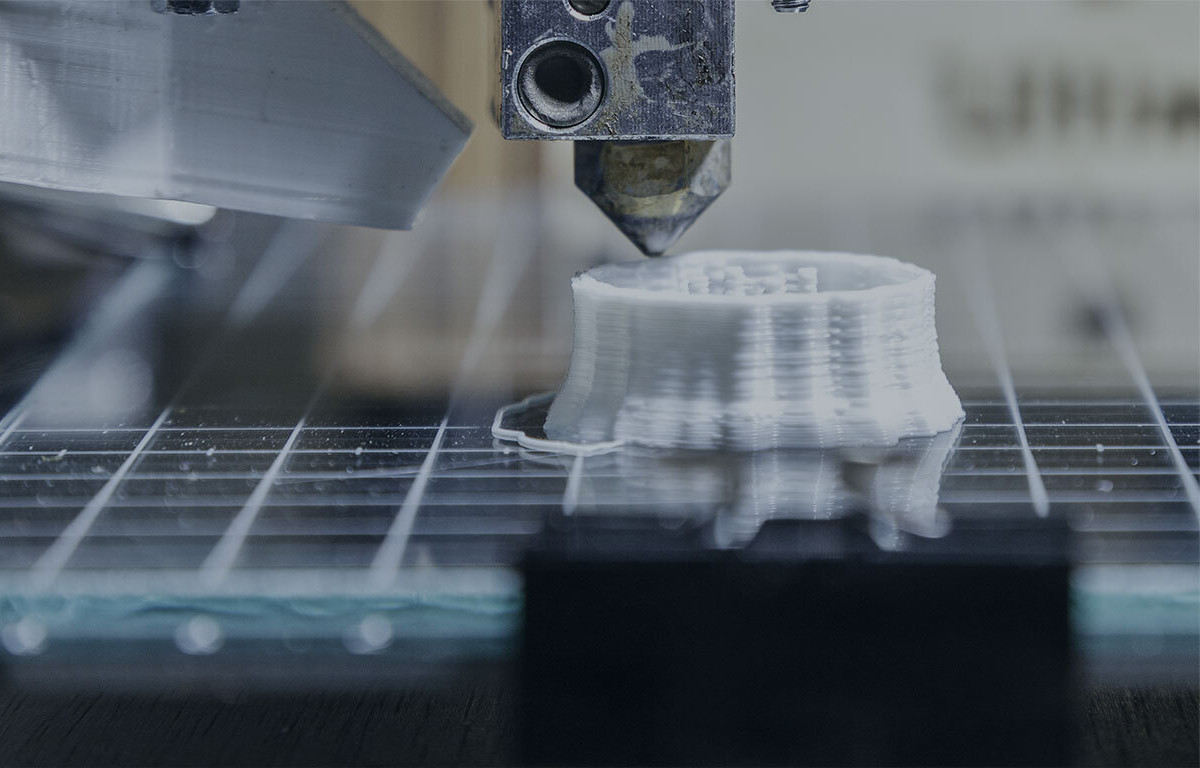

FDM is based on an additive technology, meaning that fused materials are deposited layer by layer until the process is completed. The print head moves in three directions and manages extrusion, re-building superficies according to the 3D model in the CAD.

Additive technology used in FDM offers important advantages:

- Complexity: the incremental material depository allows the easy realization of complex structures, such as undercuts;

- Magnitude: using a proper amount of material, we can build model of big dimensions, coherent with the different needs of clients;

- Speed: despite the project complexity or the magnitude, this prototyping technology allows obtaining results in a short period;

- Repeatability: models accuracy is ideal when series of products are required, ensuring prototypes always coherent with the client’s demand.

Models realised through FDM stand for their mechanical proprieties due to the material used.

PARTEC offers highly performing products:

- ABS: this thermoplastic polymer is excellent when resistance to high temperatures, hardness and good finishes are concerned.

- PC: this material is excellent for its mechanical proprieties (especially hardness and stability) and for the precision with which it can be modelled.

- PC+ABS: in this case the best qualities of both materials are combined, resulting in a highly performing material with excellent surface definition and good mechanical proprieties.

- ULTEM is high temperatures resistant material, used for those sectors who experience extreme conditions such as aviation and aerospace.

- ASA: this material combines a good mechanical resistance with an excellent aesthetic finishing. Moreover, it differentiates from other materials for its thermal stability to UV rays.

These materials are processed using our FORTUS 400MC: the machine precision and the possibility to select four different extrusion thicknesses allows reaching an accuracy of ± 0,2mm. In this way, components can be easily repeated.

Since 1999, PARTEC supports all the companies that want to easily transform their ideas info winning projects.

Discover more on our website and learn about us.