Partec Srl

Via Costa Erta, 21

24020 – Parre (BG)

P.iva 02657020166

Tel: +39 035-705800

Fax: +39 035-705820

Email: info@partec.it

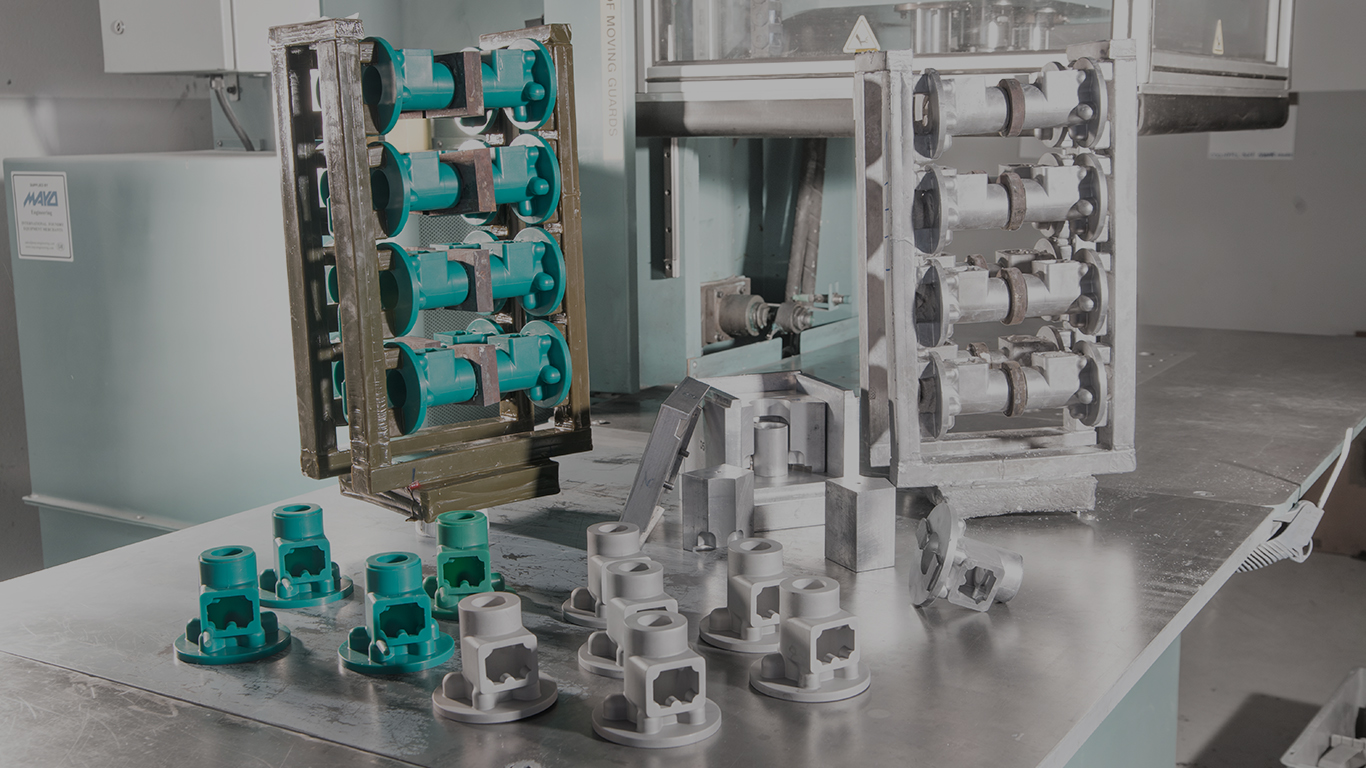

The investment casting is a process specialized in the production of all low-melting alloys that require good dimensional accuracy, high geometric complexity, undercuts, thin thickness, closed volumes, low roughness and details reproduced more faithfully than those obtainable by sand casting.

This process fits with all low-melting alloys: aluminum melts are the most requested (for example A357, EN43500..).

|

This process is used to produce castings with dimensions very closed to request, for example: compressor wheels, components for electronic equipments, fuel injection systems for aerospace industry, heat exchanger systems, jewellery.

Most of the advantages guaranteed by investment casting are:

– good surface finish

– possibility of producing complex shapes thanks to rapid prototyped patterns

– great dimensional tolerances

– high definition of the details

– slow cooling minimizes shrinkage and deformation allowing uniformity of the casting