Sintering is a process that allows the realization of solid artefacts starting from powder material: according to the filed involved, our technicians use different solicitations to aggregate dust particles and shape the product, as the client requires. Sintering can be produced through thermal, mechanical and electric energy and they can be combined in the same process to shape a wide range of products (from metals to polymers). This makes it an extremely versatile technology.

Such a principle is applied in rapid prototyping, too through the SLS (Selective Laser Sintering). It is an additive prototyping technology, meaning that the artefact is built layer by layer according to the information in the CAD.

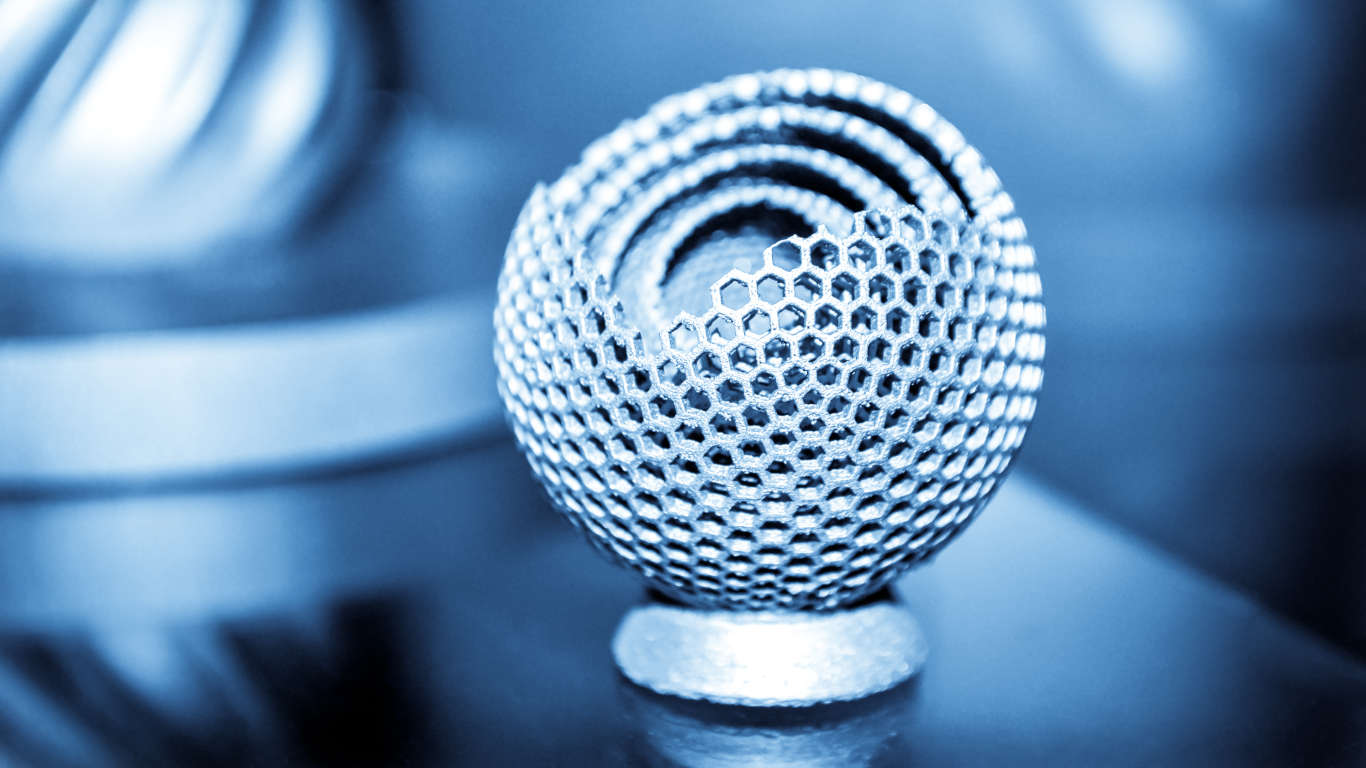

As the name suggests, SLS relies on a laser to solicit the dusts and compact them until they get a solid shape. Our technicians work on specific areas to select the proper area to solidify: lasers are much more precise and energetically efficient than fusion solutions. Differently from stereolithography, there are no mounts required since the dust in the tub sustains the piece during the building: such a process allows the realization of complex shapes without problems related to mounts to remove during the finishing phase.

The base material, e.g. nylon, can be uploaded together with other materials to improve the models mechanical performances: for instance, aluminium glass powder or carbon glass powder can be added. Partec can also rely on polystyrene used to build sacrificals used in the fusion process.

The material ensures the possibility to make post-processing finishing such as drilling, holes threading, assembly by couplings and welding. In this way, big artefacts can be realised unifying smaller components separately created. Since nylon resists to high temperatures, 3D printings can be metalized (this process is not realised with all the materials).

These advantages are paired with a low expenditure, making SLS the ideal solution for small dimension lots, but also for prototypes destined to tests.

PARTEC can also realize big monolithic thanks to his machine EOS P700 whose working surface is 700x580x380 mm. Since 1999, PARTEC is the ideal support for all those companies that want to rapidly change their ideas in winning projects.

Contacts us to learn how to shape your projects.