Processes automation is the key element that allows a distinction between past and present techniques. Thanks to more and more performant technologies, the time lapse between the project and the physical concretisation of the project is shorter and shorter.

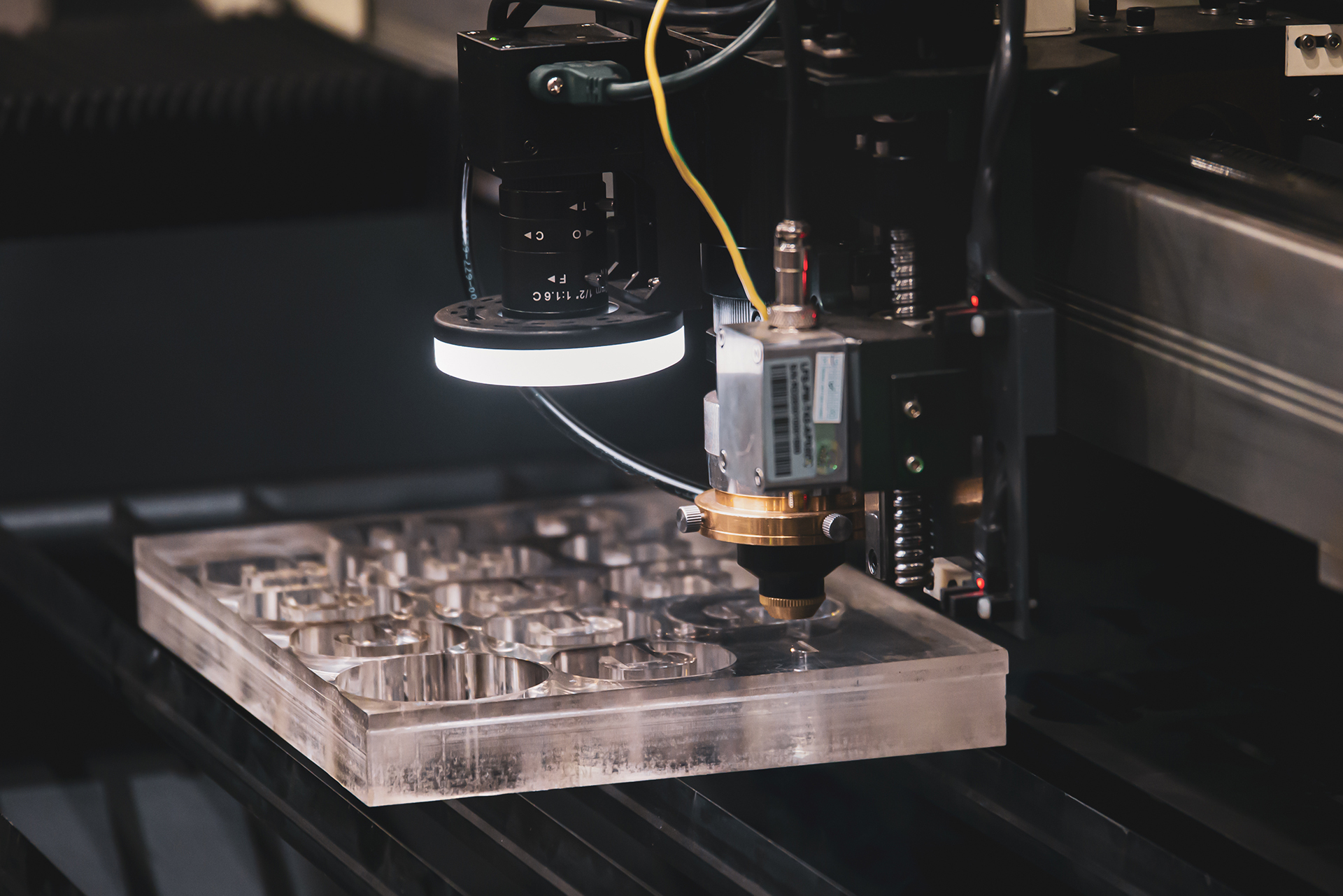

Among PARTEC technologies, there is Computer Numerical Control, best known as CNC.

As we can learn from its name, CNC is a system that allows movements coordination of a machine through strings of code to program all the actions that have to be done during the process.

CNC offers important advantages, among which there are:

- Rapidity: the possibility to make the whole machine process come true thanks to a single process. This clearly diminishes production time.

- Automation: once the program is correctly set, the machine works autonomously, so that workers can do other jobs.

- Precision: since all the movements are controlled by the program, the process tolerance is 0,1 mm.

- Repeatability: therefore, CNC allows obtaining identical components, ensuring coherence among products and facilitating serialization.

Thanks to these characteristics, CNC is a useful method in rapid prototyping.

PARTEC used the Computer Numerical Control to mill both plastic and metal material.

Inserting 3D superficies in the computer, the working process is completely automated and perfectly precise. Parts are removed from the initial block to obtain the desired prototype.

The last arrival in PARTEC is Mikron MILL E 700 U with 5 movable axis.

This configuration offers an excellent flexibility and the possibility of simultaneous interpolation: if a machine with 3 axis needs to be stopped and restarted many times to redirect the tool, in a 5-axis machine time is saved and rotation is automatic.

Mikron MILL E 700 U has 5 pallets and a 120 pieces tool store to ensure maximum versatility. The control system Heidenhain ITNC 640 ensures that the 5 axis are managed with the maximum precision, resulting in a 0,1 mm tolerance.

Tht 5-axis process has significant advantages, among which lower shipping time, higher efficiency and longer tool life.

PARTEC offers a large materials variety which are used in the final applications, such as ABS, polymethylmethacrylate (PMMA), polycarbonate (PC), brass, zamac, aluminium and steel in different alloys. In this way, we offer the highest possible coherence between the final product and the prototype and more accurate studies can be performed. Prototypes can also have demonstration purposes and they can me made even more real thanks to superficial treatments.

Since 1999, PARTEC is the support reality for those companies, which want to shape their ideas into winning projects. Discover more about us on our website and social media.