Rapid prototyping is a process that allows the realization of a physical model starting from a digital project in a short period of time and with low costs thanks to the automation and the use of less expensive technologies compared to the final ones.

Rapid prototyping relies on different techniques and technologies to realise 3D models, so that a big range of solutions is proposed to the client, which will satisfy his specific needs.

Apart from the technology selected, the prototyping process involves the following phases:

- Acquisition of the 3D model;

- Analysis of the model and conversion into a STL file;

- Elaboration of the STL file to shape the physical product correctly;

- Concretization of the prototype;

- Finishing applications.

The first step is about obtaining a CAD (Computer-Aided Design) to realise a digital 3D artefacts, characterised by a high dimensional precision and attention to details.

Reverse engineering is the alternative when CAD cannot be provided. Starting from an existing object, our technicians get the CAD through the item scanning to generate that the skeleton for model construction.

The second phase is the conversion of the project into a STL file (Standard Triangulation Language): such a standard graphic transforms CAD project superficies in links with triangular elements, offering a high dimensional precision directly linked to the number of triangles in which the image is divided.

The STL file must be elaborated further through specific software dedicated to the 3D model analysis, so that errors can be detected and corrected.

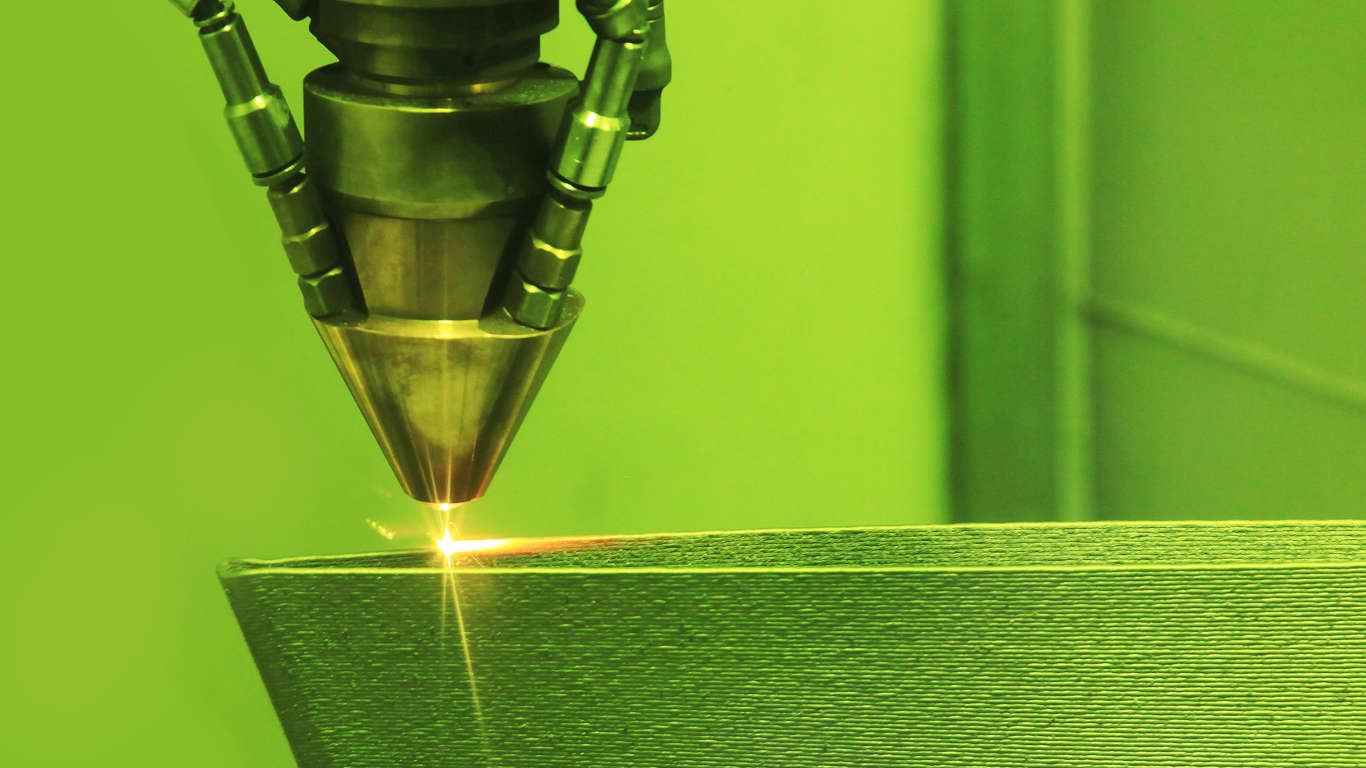

Now the file is ready for the additive rapid prototyping: machines build the physical 3D model relying on the initial digital project, which is managed by our specialised technicians whose work is to detect the best positioning of the component.

In the end, specific treatment of the 3D model obtained to apply particular finishing can be done. In this way, new properties can be added to the prototype, ideal for specific tests.

PARTEC gives assistance to the client during the modifications of the CAD file if necessary and accepts file STP, STL, IGES e CATPart. Once the file reaches our offices, we analyse it and, according to the client’s requests, we determine the best technology to solve the problem presented.

After that, the file is sent to the productive department, where our staff carefully realises the product and ships it on time.

Since 1999, PARTEC supports all those companies that want to rapidly change their ideas in winning projects. Contact us to get more information of our working methodologies.