Rapid prototyping relies on different techniques to print prototypes, which could be defined as products realised to study every component of the final product before moving on to the next production step.

Prototypes realization is definitely not a last year’s innovation, but in the past, this activity used to be manual, through carving wood and metal using long-lasting processes.

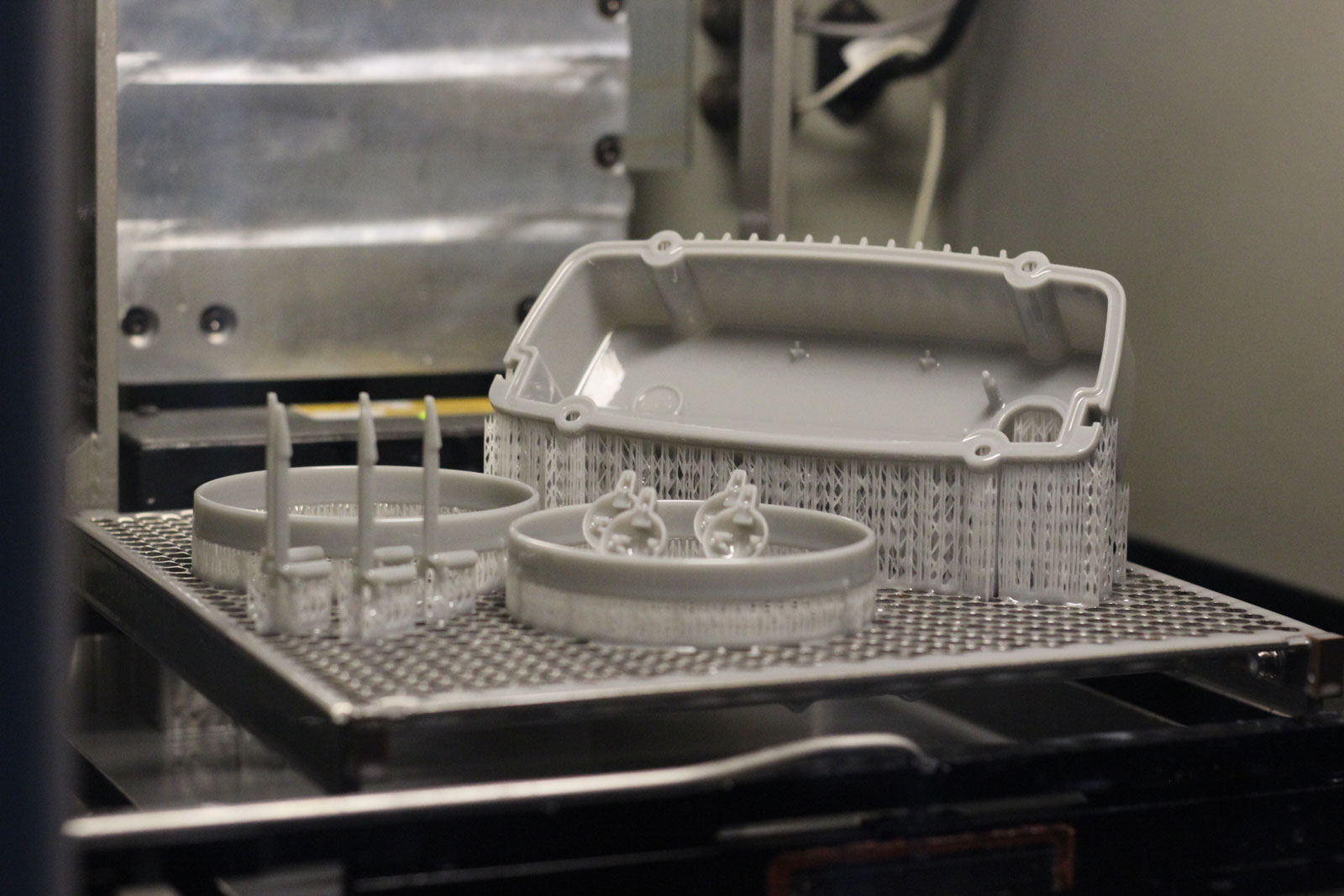

Nowadays, technology ensures the development of the previously mentioned activities through machines that facilitate the process, build the model layer-by-layer though additive manufacturing and rely on synthetic materials such as epoxy resins and nylon.

Such process is called “rapid”, since compared to traditional techniques models can be built in a shorter time.

However, we should analyse reasons to invest in rapid prototyping.

Prototypes have a crucial role for both designer and planners since they allow them to have a concrete reproduction of their ideas, without implementing final production techniques and materials. In this way, aesthetic value, dimension, functionality and usability can be identified and improvements can be added. Such a concrete comparison easily show defects that are not visible on paper.

The marketing and commercial departments often require prototypes, too. In this way, products can be presented to clients, investors and visitors in advance to get feedback before starting production.

The economic advantage is not only connected to prototyping, but also potential costs that are prevented. Defects identifies are not transposed on the final product and series come out perfect, so that products do not have to be withdrawn from the market.

Rapid prototyping is the best solution to satisfy this need since it relies on a big material range and superficial treatments to reproduce with maximum fidelity all the characteristics the final model should have.

Considering the likelihood degree, prototypes can also be directly implemented as final products, meaning that prototyping can also be used when technical support and speed are crucial elements in the production.

Rapid prototyping also allows the prototype realization in a short period and it parallel ensures different versions can be produced and confronted: quality is positively impacted and clients are happier, so that development and design times stays the same.

Since 1999, PARTEC is the perfect company for all those clients who want to rapidly transform their ideas in winning projects.

Discover more on our website and social media page or contact us to get additional information.